| Historie |

|

|

Arnold Koch

Around 1920, Mr. Arnold Koch began his career in Hamburg as a tallyman. He came from Bremen, where he worked as a master cooper in the foreign-trade company C.Melchers & Co.. Here in Hamburg, he represented the interests of the company C.Melchers & Co., which were mainly the import of raw materials from East Asia and from West and East Africa, such as silk cocoons, egg products, feathers, wood oils, hides and skins. With the entry in the commercial register on January 23, 1923 only the authentic founding date is recorded. Any additional documentation in all probability has been destroyed in the bombings. From oral tradition. The company name "ARNOLD KOCH JR" came about because there has already existed a butcher company with the name Arnold Koch. "Then I'm a junior“ Arnold Koch is alleged to have said and shortly after the company "Arnold Koch jr.“ was created and registered. The storage areas in the warehouse district were initially located at Kehrwieder, until the war mainly in the warehouses 5 - 8. At that time it was still possible to rent premises short or medium term as required, which is why temporarily up to 28 floors were used simultaneously.

|

|

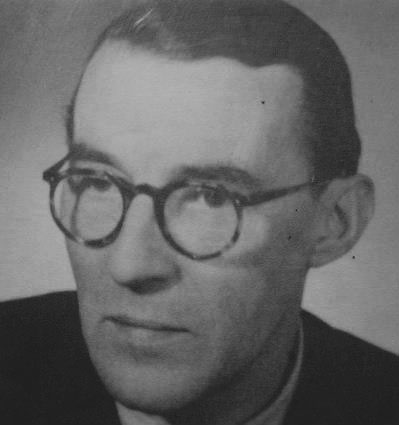

Wilhelm König

In 1931, the nephew of Arnold Koch, Wilhelm König, born 05.18.1901, joined the company Arnold Koch jr.. Wilhelm König was the son of Adolf König, brother of Mrs. Frieda Koch, née König.

On May 17, 1936, the company's founder, Arnold Koch died at the age of 69 years. As specified in the agreement, dated 19.12.1936 between Wilhelm König and the family, Wilhelm König took over the company Arnold Koch jr. As sole owner. The contract was signed by Mrs. Frieda Koch and the sister of Arnold Koch, Mrs. Henny Fischborn with husband William Fischborn and Miss Anna Koch.

At this time, not only the current imports of C.Melchers & Co. via Hamburg were supervised and taken care of, but also new customers from Hamburg were recruited and the number of items widened. Hans Neumann was the warehouse manager at the time, he had his place on the 1. floor. He had a podium with balustrade and a high desk opposite the door to the floor. At this time, the receipt and storage of silk cocoons was one of the principal activities. With these already on the quay was a lot of work and control necessary. At this time goods extended by tapioca flour, apricot kernels and green coffee. These products required a lot of weighing and control. Silk cocoons in bales were very bulky and require considerable storage space. This good has been almost exclusively taken outboard from the „Schuten“, a special kind of ship. Due to the bulkiness of the bales the Schuten were loaded up to far above the deck, so they were only able to pass at low water under the bridges in the canals.

These outboard shipments aboard the East Asia-ships "Scharnhorst" and "Gneisenau" of the North German Lloyd and loading of the Schuten recordings still exist. The storage of silk cocoons made it necessary to have specially trained cats to catch rats on each floor. Embedded in the silk cocoon the dead caterpillar attracted the rats almost magically. Once nibbled and the cocoon was worthless. In the warehouses at Kehrwieder (built in 1880) were still the old hand operated winches, whose tension cables and brake cables went from the basement up to the 6. floor through the entire house, which was an ideal transport opportunity for rats. The 2nd World War brought the import to almost complete halt. Silk for parachute-manufacturing became a very important good and the import was only sparsely continuing from China over Russia by train. In the bombing-nights of August 1943, the warehouses at Kehrwieder 5 were completely destroyed by incendiary. In this block was also Arnold Koch Jr.'s office on the 2nd floor. Through this event obviously the entire records and documents that existed since the founding were destroyed forever. No documents about the beginning of activities in Hamburg were found, so that the only known reference is the entry of 23 January 1923 at the Hamburg Chamber of Commerce.

In later bombings then some warehouses at Kehrwieder 8 and the new Wandrahm were damaged. As yet known, the company Arnold Koch jr. came by warehouses at Brooktorkai and Holländischen Brook. Wilhelm König was exempted and worked as a air raid warden in the warehouse district. Now, instead of imported goods from around the world, by order of AKE (department for war-important use) now equipment of all kinds was stored in the warehouses. There was everything stored from goulash cannons to folding beds and blankets to cookware and cutlery, so everything which was necessary for the establishment of camps. In further night-attacks by the Bomb Squad the wardens and the fire brigade had a lot to do. However, the new warehouses, built 1900, on Brooktorkai and Old Wandrahm were entirely made of concrete, so incendiary bombs were only able to break trough the top floors. I remember an explosive bomb hitting neighboring house Brooktorkai, where it only came to 4. floor. After all, these floors have a capacity of 3.5 tons per square meter in the basement and 2.5 tons per square meter in 5. floor. After the end of the war in May 1945, the floors were cleared and, as far as I can remember, American wheat flour and brown sugar from Cuba was stored there due to the Marshall Plan.

For the company Devrient, which got the license for the production of DDT by the company Geigy in Switzerland, significant amounts of anti louse powder were stored there in canisters, waiting for the returning prisoners of war. With time the import trade was growing slowly and partially new acquired customers filled the warehouse with green coffee, egg products, dry fruits, spices, canned goods and intestines. The range of products had shifted. However, products from East Asia still took much space. Especially egg products from China, such as dried egg yolk, egg white and egg yolk crystal in barrels were stored on the floors. At this time, the quality testing especially of these products increased significantly, on some days egg yolk up to 200 samples were separately taken and checked with respect to color and increased FFA content. (There are still images existing of the typical egg yolk and egg white boxes, wooden boxes with metal lined) Since the pasta industry insisted that the required yolk had to have a strong yellow color, which was not possible in the winter months, during that period increasingly more blended with duck egg yolk for achieving a darker color. However, due to that fact a lot of goods were infected with salmonella. This has led to extensive testing and inspections of imported goods by the health authorities. Meanwhile, the Dutch and the Danes increased the manufacturing of egg products, which caused that the import shifted to these countries. Silk cocoons were no longer imported after the world war. China exported finished silk fabric from Honan and Shantung. After the war, Wilhelm König was 1st chairman in the 1886 founded "Club Hamburgischer Quartiersleute von 1886 e.V.“ for some years and was for some time in the supervisory board of „Hamburger Hafen und Logistik AG“.

|

Three generations united on the 75. anniversary in Harbor Club Hamburg. Fritz W. König, Moritz König, Manfred König

|

Fritz-Wilhelm König, son Manfred and grandson Moritz

After a 3-year apprenticeship as a laboratory assistant in the chem. factory Devrient and Norddeutsche Affinerie the son Fritz Wilhelm König joined the company in April 1952 and in 1995 was awarded proxy.

In 1952, the first oriental carpets from Persia were stored on the 4. floor. For the company Riza Tchouhadji a 100 m²-shed was set up.

Henry Petersen was warehouse manager after the war, Franz Fülscher was tallyman which was for handling, sampling and the repair of the still packed in wooden casks articles a very important craft. These included, for example, liquid egg yolk (with benzoic acid preserved), fruit pulp (with sulfur dioxide conserved) and also wines in so-called „Halbstücken“. After the death of his father Wilhelm König on May 15, 1961, the son took over the company. The activities were further expanded, increasingly damage processing has been performed. Among the former products especially dried fruits of all kinds, as well as nuts and kernels were added. Especially hazelnuts from Turkey and Brazil and Brazil nuts from the Amazon area, going from Belem to Manaus and further to Peru, took much space at that time. Especially Brazil nuts were very work-intensive. From the reception on board as bulk cargo with outboard weighing, transfer to the Schuten and put loosely in baskets to storage in bulk up to about 1.5m height. In between, air shafts were made so that the goods could dry from storage in June / July to filling in October / November.

Now and then the goods were, depending on the nature of it, shoveled once or several times and then the moldy nuts were collected. Caused by the drying, a weight loss up to 12% was normal. However, the quality and taste of natural dried Brazil nut cannot be compared with today’s in drying furnace treated nut.

|